» Copper Coil

The company is one of the major Manufacturers, Exporters and Suppliers of Copper Coils in Thane (India) with a reputation of product excellence and reliability. The wide range of high quality, soft annealed, single/double layer, plain and plastic coated Copper Coils are used in diverse applications. Superior dimensional control of the Copper Coils offers trouble free performance and cost saving. The Copper Coil ends are capped at both ends to maintain the standard of cleanliness. The company delivers high quality plastic coated Copper Coils designed for protection against aggressive environment and color coded to aid identification.

Specifications Of Copper Coils :

Outer Diameter : 3.15 mm to 22.00 mm

Wall Thickness: 0.45 mm and above.

Outside diameter tolerance : +0.0/-0.08mm (0.003o)

Annealed at : Approximately 600oC

Hardness range: 45/60 HV5.

Available in length between 5 meters and 30 meters.

Available in single/double layer to match the requirement.

About Copper Coils:

Characterized by a bright, clean and dry outside and inside surface

Delivered with close ends to guarantee high internal cleanness

Available with PVC coating of blue, black or yellow color with PVC thickness of 0.50 mm or 1.00mm

Can be hand straightened or bent as required using standard benders

End Applications of Copper Coils:

Refrigeration and air conditioning

Oil and gas lines

General engineering applications

Standards

Phosphorus deoxidized copper (DLP) |

Standard |

ASTM B –75 |

BS 2871 |

JIS H 3300 |

DIN 1787 |

Symbol |

C 12000 |

C106 |

C 1201 |

SW-CU |

Phosphorus deoxidized copper (DHP) |

Standard |

ASTM B-68 |

BS 2871 |

JIS H 3300 |

DIN 1785 |

Symbol |

C -12200 |

C 106 |

C 1220 |

SF-CU |

Tough Pitch Copper (ETP) |

Standard |

ASTM B-188 |

BS 2871 |

JIS H 3300 |

DIN 1787 |

Symbol |

C 11000 |

C 101 |

C 1100 |

ECU 58 |

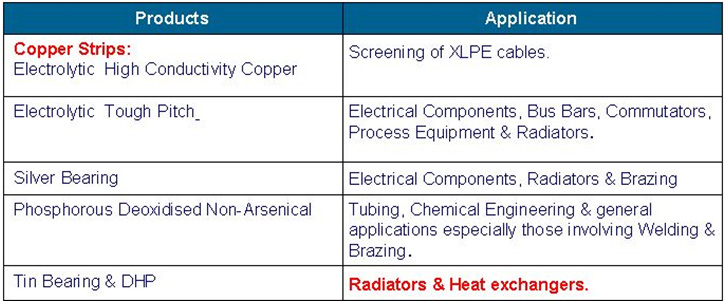

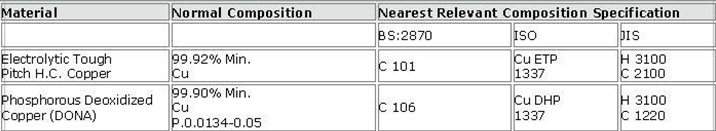

» Copper Coils & Strips

We supply HIGH quality Copper Coils & Strips in various regions of India. Our flawless copper coils are highly used for effective and everlasting usage. So come forth and avail the opportunity of purchasing durable quality copper coils as per your requirements and grades.

SIZE

Thickness: 0.05 MM to 2 MM

Width: 4 MM to 406 MM

Hardness: Soft, Quarter Hard, Half Hard, 3/4 Hard, Hard, Extra Hard and Spring Hard.

» Copper Sheets

We supply stringent quality Copper Sheets to various regions of India. Copper sheets supplied and wholesaled by our firm is of robust and tough quality. Furthermore, our superior quality copper sheets are highly resistant to corrosion and rust.

Size

THICKNESS: 0.10MM TO 10MM

SIZE: 14 INCH X 48 INCH

16 INCH X 48 INCH

24 INCH X 48 INCH

48 INCH X 48 INCH

48 INCH X 96 INCH

HARDNESS: SOFT,QUARTER HARD, HALF HARD, 3/4 HARD, HARD, EXTRA HARD AND SPRING HARD

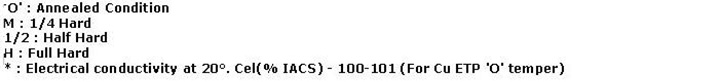

» Copper Rods

We are One of the Preferred Supplier and Wholesaler of Copper Rods. On the Basis of High Quality Products Offered By Us, We have Occupied a Standard Market Place in India. Our Copper Rods are Widely Used for Forming Electric Panels, Anodes Etc. These Copper Rods are Available in all Sizes and Shapes. We also have Electrolytic and Commercial Quality in It.

SIZE

Diameter: 5 MM to 125 MM

Length: 10 Feet to 16 Feet

Applications

· Electrical Engineering

· Panels earthing,

· Electrification lines

· Anodes

· Components

· Auto Components

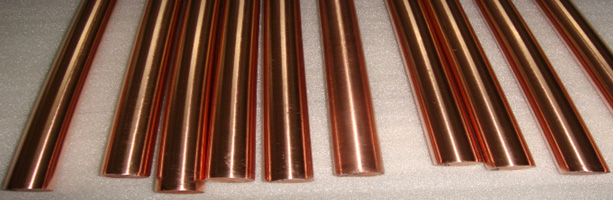

» Copper Flats

We Supply Stringent Quality Copper Flats to Various Regions of India. Furthermore, Our Superior Quality Copper Flats are Highly Resistant to Corrosion and Rust. We also have Electrolytic as Well as Commercial Quality.

SIZE

Thickness: 1.5 MM to 100 MM

Width: 15 MM to 200 MM

Length: 10 FEET TO 16 FEET

Application

Automobiles and railways

Wide Range of Electrical Industries. eg. Switch gears, Connectors etc.

Transformers & Circuit Breaker Terminals

Electrical Holders & Clamps

Distillation & Sugar Industry

· Transformer connectors

· Ferro Alloy Plants

· Steel Plants

· Refining Plants

· Cell houses

· Furnace manufacturers

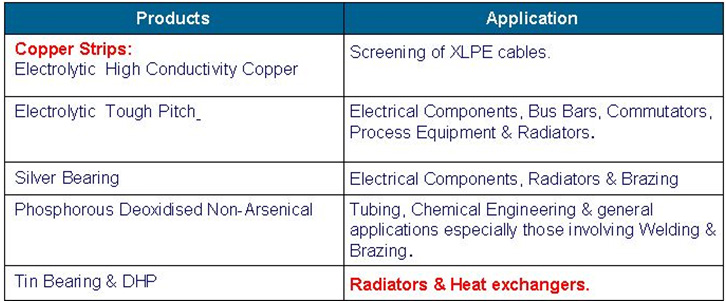

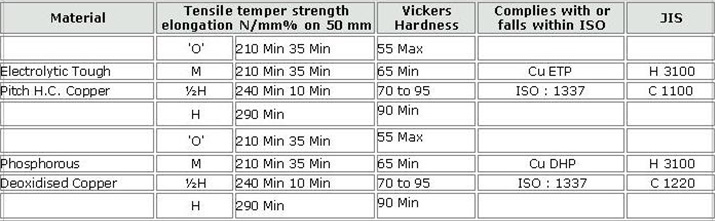

Chemical Composition:

Specification

» Chromium Zirconium Copper Alloys

Chromium zirconium copper alloy is used in areas where good mechanical properties are required to work in high electrical and thermal conductivity. This is a high strength, seam, high conductivity alloy for spot, butt and projection welding which is ideal for plain as well as coated and galvanized sheets.

Standards

Indian Standard: IS 8365

International Standards: ASTM C-18150, DIN 17666 WN 2.1293, BS 2874 CC 102, ISO CuCrZr, BS EN CW106C

Chemical Composition

Cr = 0.5 -1.2 %

Zr = 0.03 -0.30%

Cu = Balance

Mechanical Properties

| |

T.S. |

Y.S.0.2 |

E % |

Hardness |

| |

M.P.A. |

M.P.A. |

|

HRB |

| |

Min |

Min |

Min |

Min |

Rods < Dia 40 |

490 |

390 |

8 |

75 |

Rods >Dia 40 |

400 |

350 |

10 |

68 |

Wheels/Forgings |

350 |

260 |

15 |

65 |

Physical Properties

| Density |

8.9 g/cc |

Thermal Conductivity : |

>0.77 cal/cm.cm²/s/°C |

Electrical Conductivity : |

>75% IACS |

Softening Temp. : |

500°C |

» Nickel / Cobalt Beryllium Copper Alloys

Nickel / Cobalt Beryllium Copper Alloy is a high strength alloy and is ideal for spot and seam projection welding of high temperatures and high strength stainless steel.

Standards

Indian Standard: IS 8365

International Standards

ASTM B 441 |

C-17510 |

C-17500 |

-- |

Din 17666 WN |

2.09 |

2.13 |

appr.2.1285 |

ISO |

CuNi2 Be |

CuCo2Be |

CuCoiNibe |

BS EN |

CW 104 C |

CW 110 C |

CW 103 C |

Chemical Composition : (%)

NiBeCu |

CoBeCu |

CoNiBeCu |

Ni= 1.4 -2.2 |

Co = 2.0-2.7 |

Co = 0.8-1.3 |

Be = 0.2 -0.6 |

Be = 0.4-0.7 |

Ni = 0.8-1.3 |

Cu = Balance |

Cu = Balance |

Bc = 0.4 -0.7 |

|

|

Cu = Balance |

Physical Properties

Density |

8.8g/cc |

Thermal Conductivity |

>0.47 cal/cm.cm²/s/°C |

Electrical Conductivity |

> 45% IACS |

Softening Temp |

500°C |

Mechanical Properties

| |

T.S. |

Y.S.0.2 |

E % |

Hardness |

| |

M.P.A. |

M.P.A. |

|

HRB |

| |

Min |

Min |

Min |

Min |

Rods < Dia 40 |

650 |

540 |

8 |

95 |

Rods > Dia 40 Wheels/Forgings |

590 |

490 |

8 |

92 |

» Beryllium Copper Alloys

Beryllium copper alloy is a high strength alloy with non-sparking and non-magnetic qualities. The alloy supports outstanding metalworking, forming and machining and is suitable for the shafts of seam welding machines, for electrode holders, inserts for dies and load bearing components.

Standards

Indian Standard: IS 8365

International Standards

ASTM B196 C-17200, DIN 17672 WN2.1247, ISO CuBe2, BS EN CW101C

Chemical Composition: (%)

Be = 1.8 -2.1 |

Co = 0.2-0.6 |

Cu = Balance |

Physical Properties

Density |

8.3 g/cc |

Thermal Conductivity: |

>0.3 cal/cm.cm²/s/°C |

Electrical Conductivity: |

> 22% IACS |

Softening Temp.: |

300°C |

Mechanical Properties

T.S. |

Y.S.0.2 |

E % |

Hardness |

M.P.A. |

M.P.A. |

|

HRC |

Min |

Min |

Min |

Min |

1050 |

850 |

2 |

35 |

» Tellurium Copper Alloys

Tellurium Copper Alloy is known for its high conductivity (90% IACS) and high machinability (90) which makes it ideal choice for making electrical parts that require extensive machining especially on automatic/CNC machines. Also, this range is highly suitable for gas nozzles and electrical components.

Standards

International Standards

ASTM B301 C-14500, DIN 17666 WN 2.1546, BS 2874 C 109, ISO CuTe, BS EN CW118C

Chemical Composition: (%)

Te = 0.3 -0.7 |

P = 0.004 -0.012 |

Cu = Balance |

Physical Properties

Density |

8.9 g/cc |

Thermal Conductivity: |

>0.8 cal/cm.cm²/s/°C |

Electrical Conductivity: |

> 85% IACS |

Softening Temp.: |

350°C |

Mechanical Properties

T.S. |

Y.S.0.2 |

E % |

Hardness |

M.P.A. |

M.P.A. |

|

HRB |

Min |

Min |

Min |

Min |

260 |

200 |

8 |

33 |

» Zirconium Copper Alloys

Zirconium Copper Alloy is a moderate strength, high conductivity alloy used for spot and seam welding of rotor bars & rings for electric motors, aluminum alloys & bronzes, switches and circuit breakers.

Standards

Indian Standard: IS 8365

International Standards: ASTM C-15000, DIN 17666 WN 2.1580, BS 2874 CW 120 C, ISO CuZr, BS EN CW120C

Chemical Composition

Zr = 0.1 - 0.3 % |

Cu = Balance |

Mechanical Properties

|

T.S. |

Y.S.0.2 |

E % |

Hardness |

|

M.P.A. |

M.P.A. |

|

HRB |

|

Min |

Min |

Min |

Min |

Rods < Dia 25 |

350 |

310 |

13 |

60 |

Rods >= Dia 25 |

300 |

250 |

20 |

55 |

Wheels/Forgings |

200 |

160 |

45 |

40 R F |

Physical Properties

Density |

8.9 g/cc |

Thermal Conductivity: |

> 0.80 cal/cm.cm²/s/°C |

Electrical Conductivity: |

> 85% IACS |

Softening Temp.: |

500°C |

» Nickel Silicon Chromium Copper Alloys

Nickel Silicon Chromium Copper has Higher strength but lower conductivity compared to CrZrCu. Suitable for spot, seam, projection welding particularly in stainless steel and high temp. And high strength steels. Properties and application of NiSiCrCu are same as Ni/CoBeCu but it is a beryllium free alloy.

Standards

Indian Standard: IS 8365

International Standards: ASTM C-18000, DIN 17666 WN 2.0855, BS EN CW 111C

Chemical Composition: (%)

Ni = 1.8 - 3.0 |

Si = 0.4 - 0.8 |

Cr = 0.1 - 0.8 |

Cu = Balance |

Physical Properties

Density |

8.8g/cc |

Thermal Conductivity |

> 0.47 cal/cm.cm²/s/°C |

Electrical Conductivity |

> 45% IACS |

Softening Temp |

500°C |

Mechanical Properties

|

T.S. |

Y.S.0.2 |

E % |

Hardness |

|

M.P.A |

M.P.A. |

|

HRB |

|

Min |

Min |

Min |

Min |

Rods < Dia 40 |

650 |

540 |

8 |

95 |

Rods > Dia 40 Wheels/Forgings |

590 |

490 |

8 |

92 |

|