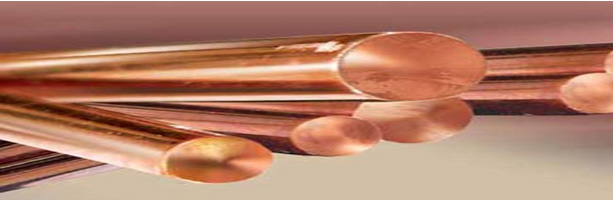

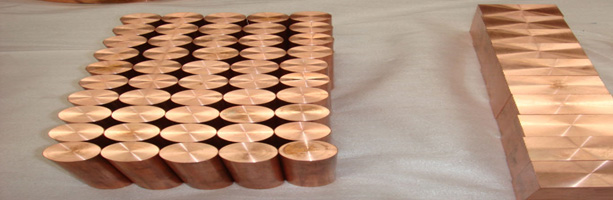

Copper are developed under the strict supervision of quality associates using best quality of materials. Widely used for variegated industrial applications, our assortment is known for their unique and outstanding characteristics such as high strength, corrosion resistance, high electric conductivity and ductility.

Forms: Electrodes, Rods, Bars, Wheels, Tips, Blocks, Flats, Wires, Strips & Tubes

Applications

Traction Motors

Large Electric Motors

Switch gears

Starters

Commutators

Power Transformers

Rectifiers, Disconnections and Circuit Breakers

Properties

Resistance to Softening

Hardness at high temperature

Technical Specification

Alloy |

RWMA CLASS |

ASTM UNS NO. |

COMPOSITION % |

HARDNESS (Rockwell) |

ELECTRICAL CONDUCTIVITY % IACS |

ZrCu |

Class-2 |

C-15000 |

Zr: 0.1 to 0.3

Cu: Balance |

Forgings: > 40 RF

Rods & Bars: > 60 RB |

85 -9 5 |

CrZrCu |

Class-2 |

C-18150 |

Cr: 0.5 to 1.2

Zr: 0.03 to 0.3

Cu: Balance |

Rods > Dia 40 and

Forgings: 65 - 80 RB

Rods < Dia 40: 75 -90 RB |

75 - 85 |

NiBeCu |

Class-3 |

B 441:

C-17510 |

Be: 0.2 to 0.6

Ni: 1.4 to 2.2 Cu: Balance |

Rods > Dia 40 and

Forgings : 92-100 RB

Rods < Dia 40 : 95-102RB |

45 - 55 |

CoBeCu |

Class-3 |

B 441:

C-17500 |

Be: 0.4 to 0.7

Co: 2.0 to 2.7

Cu: Balance |

Rods > Dia 40 and

Forgings: 92-100 RB

Rods < Dia 40: 95-102 RB |

45 - 55 |

CoNiBeCu |

Class-3 |

B.S.2874

CW103C |

Be: 0.4 to 0.7

Co: 0.8 to 1.3

Ni: 0.8 to 1.3

Cu: Balance |

Rods > Dia 40 and

Forgings: 92-100 RB

Rods < Dia 40: 95 -102RB |

45 - 55 |

NiSiCrCu |

Class-3 |

C-18000

C-64700 |

Ni: 1.6 to 2.6

Si: 0.5 to 0.8

Cr: 0.1 to 0.8

Cu: Balance |

Rods > Dia 40 and

Forgings: 90-100RB

Rods < Dia 40: 92-102RB |

40 - 55 |

Be Cu |

Class-4 |

C-17200 |

Be: 1.8 to 2.0

Co: 0.2 to 0.6

Cu: Balance |

36 - 41 RC |

22 - 28 |

0.5% Te-Cu |

|

C-14500 |

Te: 0.4 to 0.6

P: 0.004 to 0.012

Cu: Balance |

32 - 42 RB |

85 - 95 |

Copper Coil

Copper Coils & Strips

Copper Sheets

Copper Rods

Copper Flats

Chromium Zirconium Copper Alloys

Nickel / Cobalt Beryllium Copper Alloys

Beryllium Copper Alloys

Tellurium Copper Alloys

Zirconium Copper Alloys

Nickel Silicon Chromium Copper Alloys

|

|

|